A Detail Review Of PPGI Steel

Are you presently searching for a reliable source for PPGI steel? Whether you are searching for pre-coated or prepainted steel sheets or coils, you have to know that they are smartly designed and sturdy. They may provide defence against the elements, as well as block UV radiation, protecting those that are inside the structure. They are generally used as roofing sheets, wall panels, and back panels of home appliances, primarily for buildings and commercial construction projects. If you are looking at obtaining some of the best PPGI sheets available on the market, the following is an introduction to Wanzhi Steel as well as the products they have available. Here you will have a clear understanding of the PPGI steel uses, features, and differences between PPGI and PPGL, etc.

A Review Of PPGI Materials

PPGI is short for pre-painted galvanised iron. This material is made with galvanized iron (zinc coated steel). Zinc coated steel is typically produced on a galvanizing line. Then the zinc-coated steel is cleaned, pre-treated, and applied with various layers of organic coatings. The continuous process used to apply these coatings is often referred to as coil coating. The coil coating process can be used for other substrates such as galvalume steel (55% aluminium, 43.4% zinc and 1.6% silicon). However, pure zinc coated steel is referred to as PPGI. For example, PPGL is for pre-painted Al-Zn coated steel.

Making Process of PPGI Coil

The common coating process is a continuous color coating line, which includes twice coating and baking for double sides. Simply speaking, this process refers to the organic coating applied to galvanized steel sheets. In addition to the protective effect of zinc, the organic coating on the surface also plays a role in isolation and rust prevention. So its service life is longer than the galvanized sheet.

Decoiler — Welding — Rolling — Uncoiling & looping — Degreasing — Cleaning, drying passivation — Drying — Primary coating and baking — Finish coating and drying — Cooling — Packaging

Differences Between PPGI and PPGL Steel

PPGI and PPGL are two types of color coated steel. They have some great features like great corrosion resistance, beautiful appearance, etc. But there are also many differences. Let’s have a review.

As mentioned, the primary difference between PPGI and PPGL is the base metal. PPGI uses galvanized sheet, which is covered with a layer of zinc. The zinc coating provides anodic protection to the base material, prolonging the product’s service life. PPGL uses galvalume steel as substrate, which is coated with a mix of aluminium, zinc and other trace elements. The usual composition of galvalume coating is 55% aluminium, 43.4% zinc and 1.6% trace elements. While the different the base metal offers them different features.

PPGL sheets are more corrosion resistant than PPGI sheets. Also, PPGL sheets have a smoother finish as compared to PPGI sheets which are directly related to the aluminium component in PPGL. However, PPGI sheets are relatively cheaper than PPGL sheets. So, in summary, both of them contain zinc as a coating but PPGL has aluminium and silicone in addition. The lifespan of PPGL is almost double or even three times that of PPGI.

We are a team of experts with the experience to draw from in relation to advising our clients on the best pick between PPGI and PPGL sheets. But no matter whichever form of the sheet you want to purchase from us, we guarantee you that our steel sheets are durable, safe for use and great to use.

Common Coating Types

There are different coatings of PPGI and PPGL steel we used commonly. Here they are:

Polyester (PE)

It has good adhesion, rich colour, a wide range in formability and outdoor durability, medium chemical resistance, and low cost.

Silicon Modified Polyester (SMP)

SMP has good hardness, wear-resistance and heat resistance, as well as good external durability and resistance to powder, gloss retention, general flexibility and medium cost.

High Durability Polyester (HDP)

HDP has excellent color retention and UV resistance, excellent outdoor durability and resistance to powder, good adhesion of paint film, rich colour, and excellent cost performance.

Polyvinylidene Fluoride (PVDF)

It has excellent color retention and UV resistance, excellent outdoor durability and resistance to powder, excellent solvent resistance, good formability, dirty resistance, limited colour, and high cost.

Different PPGI Sheet Uses

PPGI steel can be widely used in construction, transportation, home appliances, packaging, etc. It is not necessarily limited to simply roofing projects. This will likely include air conditioning units, automatic washers, retaining walls, and also ventilation ducts. You can find them used in combination with equipment hoppers and in many cases the production of various types of stamping parts. It is highly heat resistant, and so is often made of layers of aluminum that will make it strong and light-weight. This blend of durability, as well as heat resistance, is the reason why this material is usually used in these projects.

PPGI Sheet & PPGI Coil

You can find different types of PPGI steel, namely PPGI coil and PPGI sheet. They are preferred by different groups. Below are more details.

1. PPGI Coil

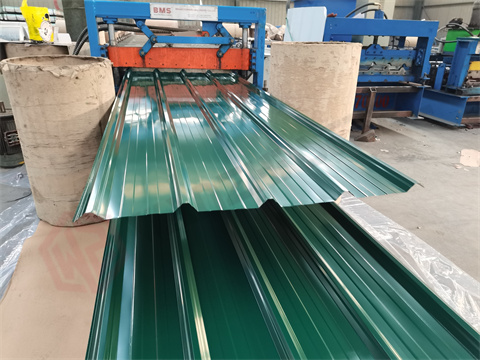

PPGI coil is a kind of raw material, which is mainly used after further processing, such as building materials. Generally, they can be cut and profiled into corrugated sheets, which can be used as roofing or wall panels. Also, it can be used to manufacture furniture, top and back panels of household appliances, etc. Most buyers of PPGI coil aim to trade or make other products. They often have big orders.

2. PPGI Sheet

PPGI sheet is a kind of end or semi-finished product. You can find PPGI plain and profile sheets on the market. The biggest use of PPGI sheets is as roofing sheets or wall panels in construction. Also, some will be used as door panels, panels for cars, ships, etc. Some buy these sheets for their own uses, while some for trading.

PPGI coil also can be made with different coating processes. For example, the PPGI sheet with single-layer back paint has poor corrosion resistance and scratch resistance, but it has good adhesion. So it is mainly applied to sandwich steel panels. While the PPGI sheet with double-layer back paint has good corrosion resistance, scratch resistance and processing performance. It is mostly used as corrugated roofing sheets, but its poor adhesion is not suitable for sandwich panels.

Some Great Benefits Of Using PPGI Steel

There are numerous different reasons to utilize this material. Heat resistance is simply one of the benefits. They are also corrosion-resistant, however, not as resistant as PPGL sheets. This is because they might not be built with a zinc coating that may provide additional effectiveness against the elements. However, they are very cost-effective in comparison. If you are planning a sizable project, PPGI is exactly what you should need. All it takes is a couple of minutes to evaluate the various ones from Wanzhi Steel to decide on the correct one for your personal project.

Why Work Together With Wanzhi Steel?

Wanzhi Steel is surely an outstanding company, an organization that is certainly known worldwide. They produce many different products including coils, corrugated sheets, galvanized strips, and many other products. additionally, they generally do have an assortment of PPGI and PPGL products available. This can include roofing materials, wall materials, and base metal products that can be used for industrial and commercial projects. There is a wide variety of designs, colours, and sizes to choose from, including plain and profile sheets, glossy or matte, solid colour or patterns, etc. Wanzhi Steel has its own factory and advanced production line to offer quality pre-painted galvanized steel sheets for sale. The thickness ranges from 0.12mm to1.2 mm and the maximum width is 1,250 mm. You can select according to your needs.

There are numerous PPGI steel uses currently available. It really depends upon the project that you are working on. Whatever the colour that you require, or the kind of corrosion resistance you would like, you will find the specific sheets within a few minutes. Remember to consider checking out other products available from Wanzhi Steel. This renowned company can provide you with the materials essential for your commercial and industrial products at very economical prices.