Since the beginning of the industrial revolution, steel has become a commodity and an essential material that makes our day to day life easier. This malleable material literally (and figuratively) shaped the modern world into what we know today!

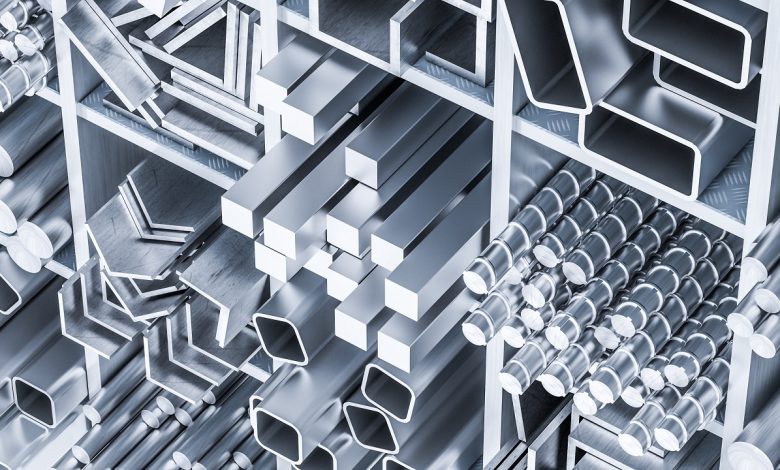

From coffee cups to automotive parts, different steel types have been used to fit our daily needs. Mainly, steel is used for its mechanical and electrical applications. Also in heavy construction equipment, kitchenware and tools. The combination of the elements iron and carbon form different types of steel and these types can be categorized into grades.

Each type of steel has its own unique physical, chemical, and environmental characteristics that can be applied to each corresponding field.

So, what are the main types of steel and its applications?

- Carbon Steel

- Stainless steel

- Alloy Steel

- Tool Steel

-

Carbon Steel

As said earlier, carbon is one of the main elements that is present in steel. It is the most common type of steel that is an alloy of iron and carbon. The relatively higher content of the element carbon (about 2%) in this steel makes it extraordinarily strong while having a low melting point – making it easily manufacturable. Despite its strength, carbon steel is very prone to corrosion when exposed to moisture.

Carbon steel is the most used (and cheapest!) among the types of steel listed as it contributes to about 90% of steel production. Based on the different amounts of carbon within the steel, the material can be broken down into 3 distinct categories:

-

Low carbon steel (0.3% carbon)

Low carbon, also known as mild steel, is the cheapest among the category of carbon steel. Because of its high malleability and ductility, it can also be used in construction beams, flat sheets, pipes, chains, wires, cases, and many more. Despite its comparatively low tensile strength characteristic, it can be improved by the process of cold-rolling. Cold rolling is the process of rolling the steel between two polished rollers under high-pressure making it easy to form into various shapes.

-

Medium carbon steel (0.3-0.6% carbon)

Medium carbon steel is stronger and more ductile than the lower carbon variation. It is used in construction of skyscrapers, fences, bridges and homes. Although it is highly malleable, it can be treated with heat tempering to increase hardening.

-

High carbon steel ( <0.6% carbon)

High carbon, also called carbon tool steel, is the hardest among the types of carbon steel making it difficult to bend, cut and weld. Because of the comparatively higher sulfur content, it is extremely brittle when worked under heat treatment. It is used in high strength wires and shock-absorbing springs because of its wear resistance properties.

-

Stainless Steel

Among the types of steel, stainless steel is probably the most familiar to an average joe. The shiny steel contains 10-20% chromium which makes it resistant to rust and corrosion while being fairly easy to form. Aside from its anti-corrosive properties, the cost effective steel displays endurance,durability, efficiency, performance, visual appeal and lightweight characteristics. It is commonly used in food, medical, automotive and architectural industries.

Stainless steel can be categorized into 3 major types by its chromium content.

- Ferritic alloys (12-17% chromium, <0.1% carbon)

Ferritic steels are composed of high amounts of chromium, nickel and other alloying elements which makes it magnetic, strong and durable. It cannot be hardened by heat treatment. However, it can be further enhanced in its strength capabilities through cold work techniques. Its magnetic properties make it useful in fastening parts and induction heating.

- Austenitic alloys (18% chromium, 8% nickel, <0.8% carbon)

Austenitic steels are the most common type of stainless steel, especially in the culinary industry. This type of stainless steel contains high traces of nickel, molybdenum and chromium content. This combination improves their resistance to corrosion but causes them to become non-magnetic. Austenitic steel is used in industries including medical, automotic, aerospace, and machinery because of its exceptional strength, malleability and for its advantage that it can be easily cleaned.

- Martensitic alloys (11-17% chromium, 0.4% nickel, 1.2% carbon)

Martensitic steels can be differentiated among the other varieties as it can be hardened and strengthened through heat and aging treatments because of its relatively higher carbon content.

-

Alloy Steel

By definition, alloy is a combination of several metals. In this context, alloy steel is fused with several metal and non-metal elements contributing to its overall strength, machinability, ductility, corrosion resistance, wear resistance and toughness. This makes alloy steel feature a variety of environmental, chemical and physical properties, depending on the amount used to alloy. Nickel, copper, aluminum, vanadium, silicon and manganese are some of the elements added and typically contribute no more than 5% to the composition of alloy steels. This makes alloy steel perfect in applications for pipelines, automotive parts, transformers, power generators and electric motors.

There are many types of alloy steel depending on the element combination used, but it is primarily grouped into two:

-

Low alloy steel

This type of alloy steel exhibits slightly higher properties when compared to carbon steel. Low alloy steel has some advantages in yield strength, creep strength, oxidation resistance, hydrogen resistance and low-temperature ductility. This type of alloy steel is useful in industries that use temperatures lower than 580 degrees. Above that threshold, the product will be compromised. It is because of the insufficient oxidation resistance the material needs in order to manage very high temperatures.

-

High alloy steel

This type of alloy steel has approximately 5% higher amount of alloying content whereas low alloy steel only contains less than 0.2%. Main alloying elements in high alloy steels are various ferrous metals for the promotion of stabilization. Also, high alloy steel contains the elements chromium and nickel that are absent in low alloy steel. This gives high alloy steel anti-corrosive properties, formability and strength.

-

Tool Steel

Last but not the least, tool steels are the combination of alloying elements like tungsten, molybdenum, cobalt and vanadium. These alloys are made in different quantities to increase heat resistance and durability, making it a perfect candidate for tools and machineries that have the priority to be impact resistant.

Examples of products that use this kind of steel include industrial tooling, drills and drilling equipment, cutting equipment, rods, rails, wires, pipes, sheets, strips, valves and other commercial or industrial equipment that requires high durability.

Key Takeaway

From the medical field to the power industry, steel has proved to be one of the most important commodities among different industries. Being a vital component in the modern world, different steel types and its grades cater to specific production goals best suited for each variant. Considering the unique properties each type possesses, the only challenge in this industry is the limitless opportunities steel provides to the world.

metin2 Pvp Serverler

1.”Mt2″ mmo forum Mmo forum

2.”Zafer2″ metin2 pvp serverler metin2 pvp

3.”EditsizserverleR” metin2 pvp serverler metin2 pvp serverler

4.”EmekserverleR” emek pvp serverler emek pvp serverler

5.”WslikserverleR” wslik pvp serverler wslik pvp serverler

6.”Metin2 pvp ServerleR” metin2 pvp serverler metin2 pvp serverler

2022 metin2 tanıtım siteleri, wslik pvp serverler, emek serverler, editsiz serverler, mmo forum tanıtımları hepsi bu listede 2022 güncel metin2 tanıtımları.